Moth Eyes Inspire Better Optics

By Kristina Mullins

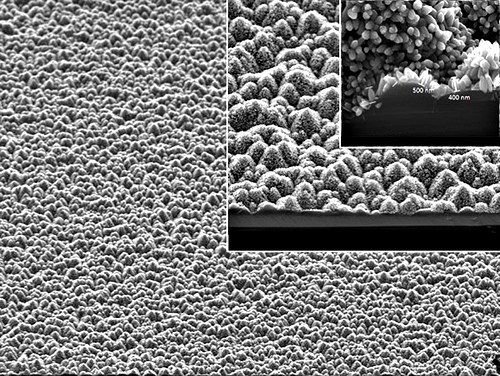

For decades, researchers have been trying to imitate moth eyes because of their ability to absorb nearly all incoming light. Moth eyes have particular surface features which resemble a grid of pyramids at the microscopic scale. The structure alters the path of incoming light and prevents it from reflecting back off the eye.

Moths gain two advantages from this eye structure. It allows them to avoid being seen easily by predators at night, and it enables them to see better since less light is "lost” to reflection. It is this second feature that has generated interest from researchers and engineers.

Recently, a research team from Oregon State University (OSU) announced the creation and patent of a marketable method for imitating this optical feat. The team, led by Chih-hung Chang, is not the first to either attempt or succeed at this endeavor, but their method to coat optical surfaces with the necessary nanostructure shows great promise to accomplish it economically.

|  |

Traditional anti-reflective coatings use several layers to alter and "trap” incoming light, according to Subhadeep Gupta of the University of Washington's physics department. Each layer is made of a material with a different index of refraction, a property that describes how light travels through the material. The result of the layering eliminates glare and improves the amount of light passed through the optics, but each extra layer adds to cost. Chang's team also takes advantage of the index of refraction. The nanostructure of both the moth eye and the OSU engineered coating create a gradual shift in the index of refraction, trapping and passing the light without multiple layers.

If the OSU coating is applied to eyeglass lenses, for example, people will be able to see better, particularly in low light conditions. That alone may be an exciting proposition for most, but the applications for the consumer and scientific community don't stop there. The OSU team's methods should be able to be applied to many materials, not just eyeglasses. Camera lenses may be a common coating target the average consumer will encounter, but this application will also be of interest to researchers. A coated optical surface will pass more light through the camera, which decreases exposure time. This means more observations can be taken in less time. In astronomy, getting time on a telescope to record data is very expensive, partly as a function of the limited time available to observe and the high cost of constructing good quality optics. The OSU coating can address both issues, driving down the price of research. Getting useful work out of the development is what has motivated Chang. "My passion is to control a process and make it useful,” he says.

The OSU coating process should also work on solar panels. Chang estimates an increase in efficiency of one to two percent, which may sound like small numbers but has the potential to make a significant impact. Since the OSU coating technique could be applied to nearly any optical surface (several have already been tested), solar panels or other optics mentioned above could be upgraded rather than completely redesigned, decreasing wasted resources.

Furthermore, the nanostructure works across many wavelengths, so coated optics are not just more efficient with visible light. That means those sporting a nanostructure coating on their glasses should be sure to get a UV protective material or coating since they would pass more of the potentially harmful radiation. However, to the researchers and engineers, this feature of passing all kinds of light is generally good news, since not all applications are geared toward the visible spectrum.

The process of coating the optics with a nanostructure is done in a chemical bath, and the reactions are controlled with a tiny chemical reactor, or microreactor. Normal chemical reactions are relatively uncontrolled in the reaction rates and yields, both of which are governed by the basic laws of physics and chemistry. The microreactor provides a great level of control over reaction rate by managing the "population” of the reactants so the team can tune chemical reactions for various materials, and it creates conditions for better heat and mass transfer, making the coating process more efficient and cost effective.

Since the technology is largely self-contained, it would be relatively simple to set up the process in the office of your local optometrist. The team is currently working out the reaction recipes for materials that are most commonly used in commercial applications, like eyeglasses, to prepare the process for public use. Their microreactor method has been patented and the team is now seeking outside funding to continue with development. The research was originally funded by a grant from the National Science Foundation.

Kristina Mullins is a senior undergraduate in physics and astronomy at the University of Washington.

Images

Top: The moth's eye highly magnified. The grid of pyramidal structures help decrease light reflection, a feature researchers try to mimic. Photo: Peng Jiang

Bottom: The nanostructure coating created by the OSU team using micro-reactor technology. Image: Seung-Yeol Han

|